Time is always a factor in business and product management. Learn how you can load your silage pit faster and cheaper with the use of our bespoke Smart Slurry Aeration System.

Slurry has become the most common manure applied to silage fields and can vary in nutrient content depending on its dry matter (DM) content. Grass silage has a large nutrient demand and adequate Nitrogen (N), Phosphorous (P) and Potassium (K) are essential for maximising grass yield and producing sufficient winter feed. Increased Nitrogen content contributes to the nutrient value of the slurry and boosts the grass regrowth rate in your silage fields. Nitrogen is in fact, the key driver of grass yield and requires a delicate balance to reach optimum levels.

Clean Air Strategy

With the livestock sector accounting for 88% of total ammonia emissions in the UK, and ammonia emissions from manure storage accounting for 9% of the UK agricultural total, the UK government are now implementing new legislation which aims to reduce this sector’s emissions, by as much as possible, via their Clean Air Strategy policy.

It is vitally important that slurry application is done at the right time on the silage ground, with the assistance of as many nutrients as possible. Commonly this application is done when closing the silage field in late March or early April, during the season.

With all of these extensive factors in mind, this is where Dairypower steps in to provide several extensive ecological and environmentally friendly solutions for all types of Slurry Management requirements.

What is Slurry Aeration

Slurry contains a mixture of gases created by bacteria during the decomposition of the slurry. These include methane, carbon dioxide, ammonia, and hydrogen sulphide. All of these gases are unpleasant, and several of them are also deadly and highly combustible. All of these have to be handled with care as a result.

Here at Dairypower, we have created an industry-leading product, Smart Slurry Aeration System which is a safer and smarter solution to the traditional one of agitating slurry, which is most commonly done with a tractor agitator.

With the rapidly increasing popularity of integrating this safer solution on beef, dairy and pig farms, our unique system has many benefits such as the elimination of tractor agitation, reduction of harmful gases such as methane and hydrogen sulphide, better air quality and greater grass regrowth. This is extremely important when growing silage and assists in increasing the production of fodder for the winter season.

Cost Effective Solutions

Dairypower already provides a range of other slurry management systems and we believe this Smart Slurry Aeration System to be the most cost-effective of all of the options. We also ensure we are consistently using environmentally friendly methods for keeping the slurry in a homogeneous, pumpable state. Since the introduction of our bespoke products to the Irish market in 1998, we have expanded to a point where there are now more than 4000 systems in operation worldwide, which is a testament to the quality and effectiveness of our flagship product.

Our smart system works on a low-pressure, high-volume basis. A roots-style blower pump and energy-efficient drive unit supply air via the Dairypower patented rotary valves to non-return outlet valves fixed to the base of the tank. Each outlet branch sequentially aerates a section of the tank, until the entire tank is fully aerated. The simple physical action of rising air bubbles mixes and moves the slurry and creates an aerobic environment with no need for any further agitation.

Hazardous Considerations

The most common practice of agitating slurry is done with a tractor agitator. Unknown to many farmers this is also the most dangerous way of preparing slurry for spreading. With tractor agitation, when the crust is initially broken, threatening and harmful gases are released. One incorrect move when agitating slurry could be fatal, and worst-case scenarios may occur when carelessly handling slurry.

The slurry contains hydrogen sulphide gas which cannot be smelled at high concentrations, with the gas usually released in substantial quantities shortly after mixing begins in any part of the tank. This is hugely unsafe for farmers and livestock, as any exposure to such gases can be catastrophic.

The Benefits of Aeration for Slurry

Traditional tractor agitation requires additional labour units and tractors on farm, as well as extensive fuel costs. Cattle have to be moved when agitating slurry, and there are always risks associated with moving eccentric cattle mid-spring in addition to creating unnecessary extra labour.

Our Smart Slurry Aeration System does not allow for a hard crust to develop on the slurry. We have completely eliminated the need for this to occur, with our patented one-of-a-kind system. This is a lot safer as it prevents the build-up of dangerous concentrations of hydrogen sulphide and methane gases, producing better air quality around your farm and yard, therefore there will be no need to move your animals.

The system also ensures complete consistency of the slurry in the pit, resulting in no blockages in tankers, and reducing machine handling whilst ensuring total safety when spreading the slurry. This is increasingly more important with the integration of Low Emissions Slurry Spreading (LESS) techniques for spreading slurry in silage grounds. These LESS techniques combined with the correct timing of application have been shown to decrease ammonia emissions by up to 30% compared with splash plate application, with the incorporation of our Smart Slurry Aeration System, imagine how much more this could be reduced!

With the current trend of fertiliser prices increasing rapidly, our system will also help further reduce chemical fertiliser usage, and make the slurry more valuable with an increase in Nitrogen values, especially ammonia Nitrogen.

Benefits of Smart Slurry Aeration System

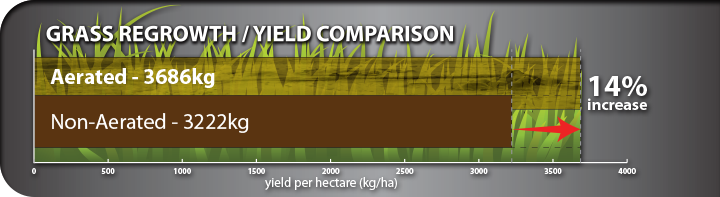

One of the most positive effects of using our Smart Slurry Aeration System is that grass regrowth increases. It has been shown that grass grown by utilising aerated slurry has recorded a 14% higher growth rate than that using non-aerated slurry which is always ready to spread.

Our system typically runs four to six times per day, and operates at a very low cost of less than £1 per day, making an average return on investment of four to six years.

Find Out More

To find out more about our cutting-edge industry-leading slurry management solutions please visit our website at www.dairypower.com and book a demonstration via our website.